Projects

Power Line 90 Port-Gentil Gabon

Planning ,supply and construction of HV SCADA for power line and 3 substation.

Base on SICAM PAS and SICAM SCC software and

IEC-61850 IEDs.

Design of PRP network for IEDs according to

IEC-61850 with Ruggedcom equipment .

On-site commissioning and integration with old

power stations

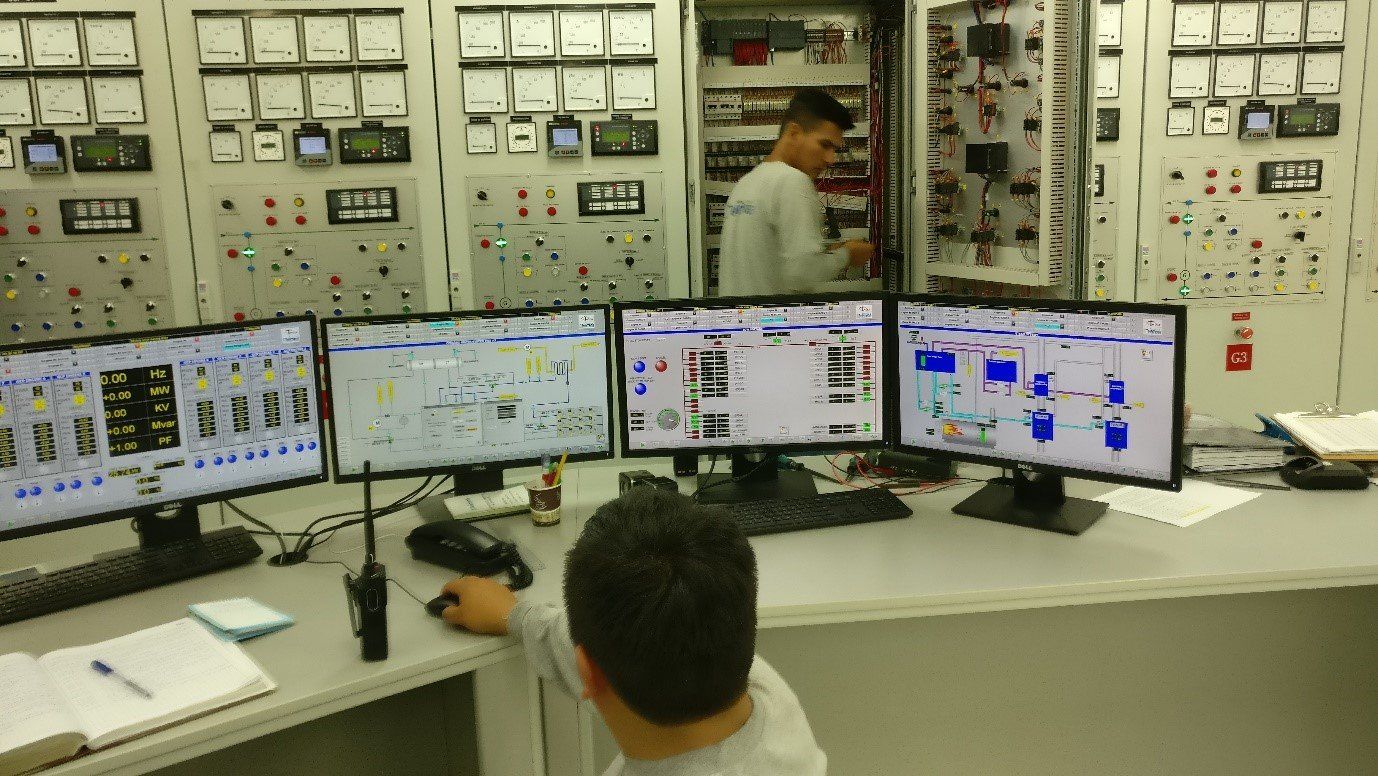

Power station at Ouagadougou Burkina Faso

Planning supply and construction of a control system for a power station at Burikina Faso

Power station use 3 MAN dual fuel 18 MW medium speed engine

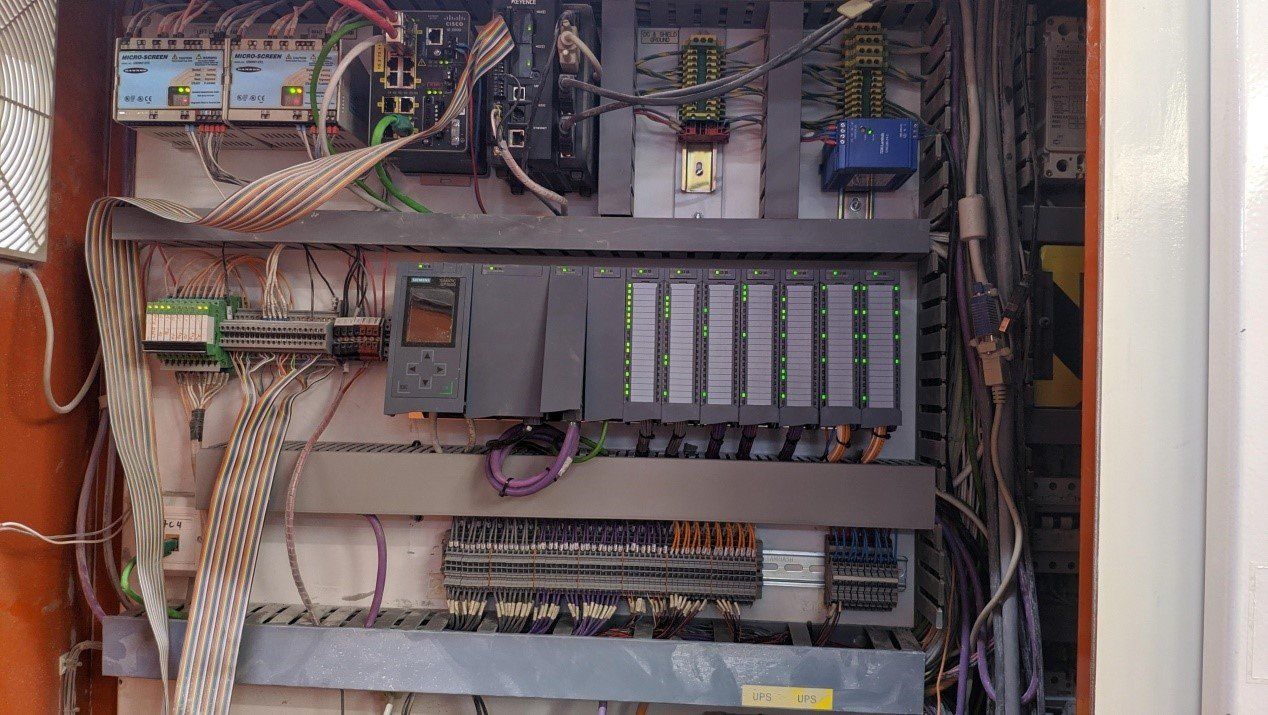

Tha control system use S7-1500- PLC with 20 RIO base on Profinet interface.

The SCADA system in WinCC 7.5 in redundant architecture the SCADA procee over 10000 externals points.

The control system enable monitor and operation of all 3th party systems (water oil fuel) and maximize the efficiency of the station.

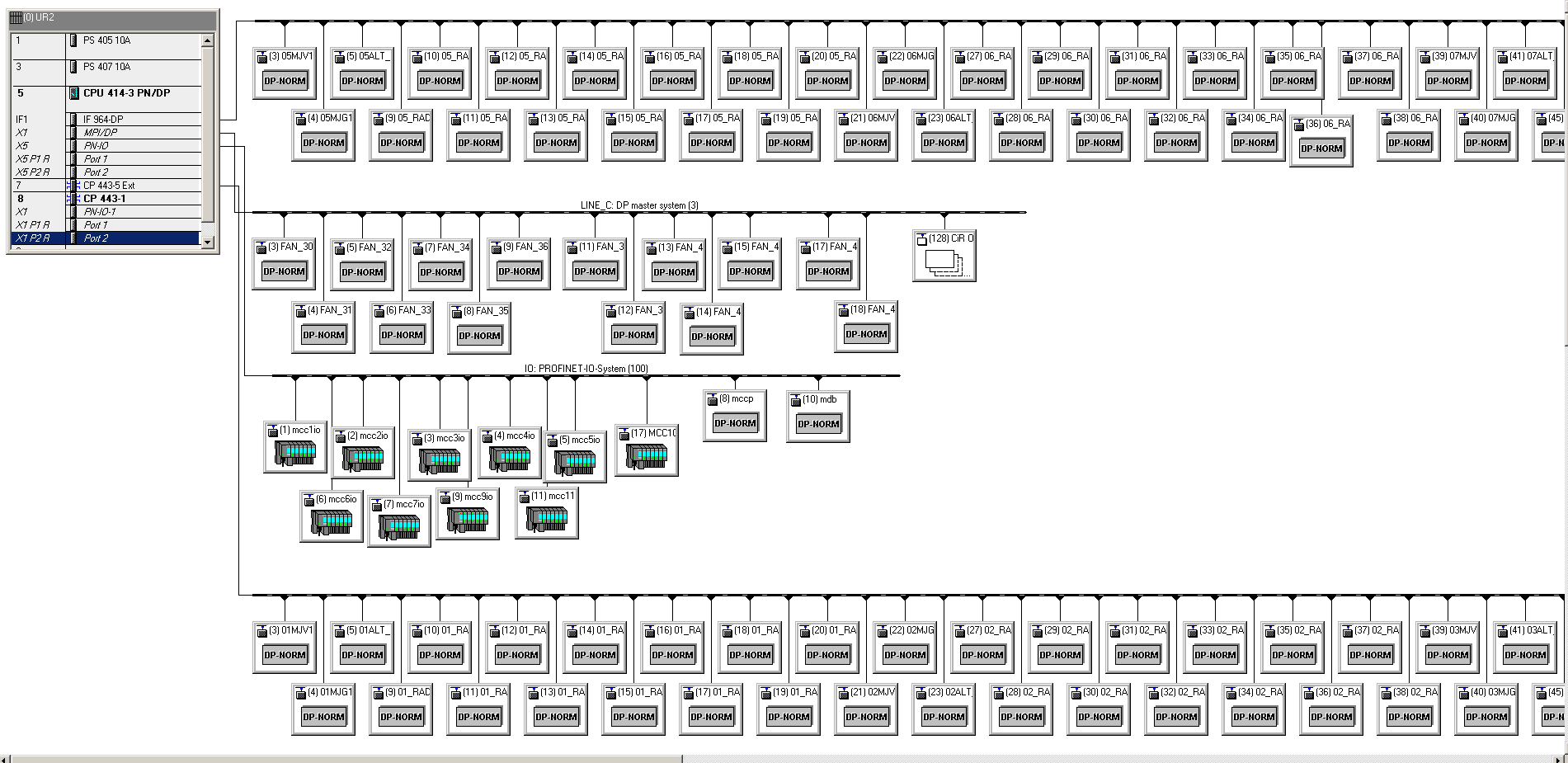

Power station at Iquitos Peru

Planning supply and construction of a control system for a power station at Iquitos Peru

Power station use 7 MAN dual fuel 11MW medium speed generators

Tha control system use S7-400- PLC with over 200 DP unit and 12 Profinet IO unit.

With 10 s7-1200 and s7-1500 as local and peripheral PLCS .

The SCADA system in WinCC 7.3 in redundant architecture the SCADA procee over 12000 externals points

The WINCC and S7-400 work in combine single engineering system (single data base) and work as DCS.

The project also includes HV SCADA system based on IEC-61850 standard using SICAM PAS by siemens

The system manages about 25 IED and communicate with remote station at IEC 60870-5-104 protocol

MORE POWER PLANT

- In Burikina-faso BOBO power station 3 units of 15MW each unit total 45MV 20000 control I/O 6000 by wire 14000 via fieldbus & communication

- In Gabon Libervil power station 4 units of 18MW each unit total 72MV 18000 control I/O 4000 by wire 14000 via fieldbus & communication

- In Gabon Port-genti power station 3 units of 18MW each unit total 55MW

- Palmeras Goyas Brazil 170MW 22000 control I/O 5000 by wire 17000 via fieldbus & communication

Biological wastewater

Development algorithm for control system of biological wastewater treatment plant. That processes variable and non-permanent quantities of wastewater from a chicken slaughterhouse.

Supply Siemens control system hardware and SCADA software.

Performing tests, and entering into use of the system.

Technical support, and implementation of changes and additions to the control system. on an ongoing basis and according to customer requirements.

More Biological wastewater

Aqwise El-Salvador The project included writing software, hardware and software supply, entering into use of the system, continuing service.

Aqwise Slovenia Vitiva The project included writing software, hardware and software supply, entering into use of the system, continuing service

Aqwise Mexico The project included writing software, hardware and software supply, entering into use of the system, continuing service

BCS for BOILER C IN DSW

Control system for BOILER that supply steam via an exiting steam header to

to an existing steam turbine

Steam pressure. 67bar

Steam temp. 510 ˚c

Steam flow. 130 t/h

Feed water temp. 105˚c

The work that was done

The system is based on MODICON and FOXBORO controllers:

There are 400 connected I/O points and more 1000 points that are seen in the fieldbus network.

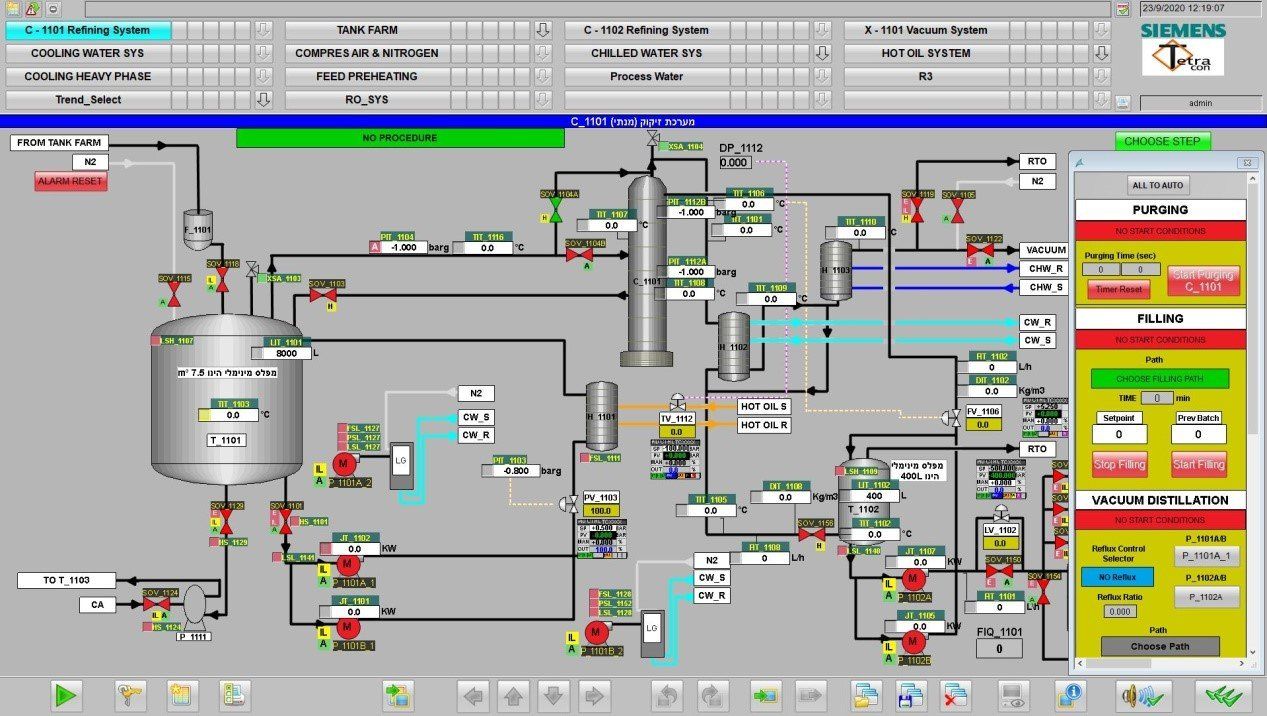

Process for solvent refining

New plant solvent refining in dimona

The control system controls the refining process, and the site of the raw materials and products

Tha control system use S7-1517- PLC with over unit and 15 Profinet unit's.

Chillers ,compressors , CWT –modbus tcp\ip

RO System- Modbus 485 to Modbus tcp\ip

Vaccum sys- s7 communication

The SCADA system WinCC 7.5 process 9000 externals points

Upgrading a control system at the Zefa site

Upgrading a control system at the Zefa site.

The control system controls a conveyor belt that transports potash from the Dead Sea Facilities

to the site of the train station, which is 18 kilometers from the Facilities

, and at an altitude of about 1000 meters above the Facilities

The old system was powered by a Modicon controller and contained over 1000 I/O.

Due to the importance of the facility it can not be disabled for long periods of time and therefore the upgrade of the control system was supposed to be done within 48 hours. Tetracon has planned to replace the Modicon PLC with Siemens PLC, including all 1000 I/O's,

Rewrote the software, Managed physical replacement of the controller in the field, and operated the facility with the new Siemens PLC. The entire process of replacing the controller in the field took only 24 hours.

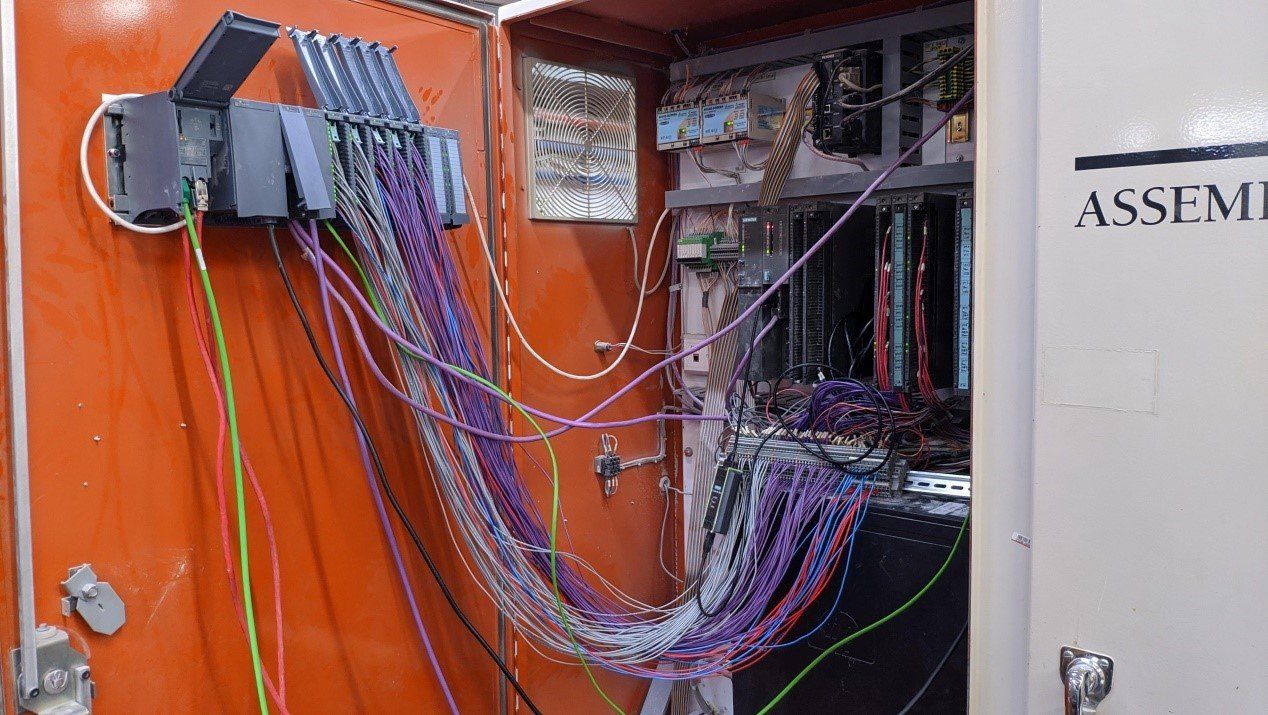

Netafim factory

Upgrading the control system of an assembly machine.

Disassembly the old controller, providing a new control system, writing new software and operating the machine

assembly machine